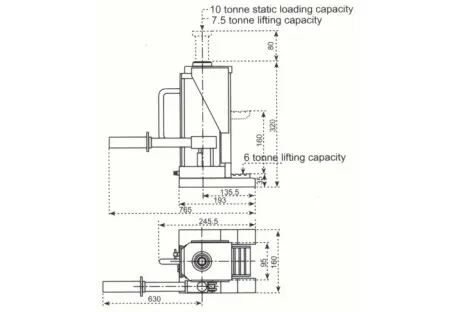

Machinery Toe Jack that can lift up to 6000Kgs on its Lifting Toe / Claw. As the name suggests these tested industrial machinery toe jacks are ideal for lifting heavy machinery or similar objects by using the toughened steel lifting toe supplied, the toe has a lifting stroke of 160mm and can lift loads that have a low floor clearance. These quality manufactured hydraulic toe jacks have been designed with a large lifting stroke that can either lift a load on its toe or head, the tow clearance is only 35mm tall, making this industrial machinery Toe Jack an ideal lifting jack that can slide under most low-level machinery.

As mentioned above, the Machine Toe Jack can be used with either the toe or the head to lift a load - If the Tow is used for lifting the max capacity is 6000Kgs (6 tonnes) the head can also be used as a lifting point and can lift loads up to 7,500Kgs (7.5 tonnes) capacity. The head can also be used to hold a load up to a capacity of 10,000 kg (10 tonnes).

The Machinery Tow Jack can be used on its own to lift machinery of large heavy objects, or it can be used in conjunction with load-moving skates and load-moving skate kits.

Model

| Capacity | Stroke | Toe Lifting Range

| Head Lifting Range | Floor Clearance

| Weight

|

TB100

| Claw 6,000Kgs Head 7,500Kgs | 160mm

| 35-195mm

| 320-560mm

| 35mm

| 25Kgs |

Supplied with a lifting handle built into the body and a pumping handle.

Supplied fully tested and certified.

How to operate the 6-tonne Machinery Toe Jack - This simple-to-operate high-capacity hydraulic tow jack is reasonable simply to use. firstly make sure the load to be lifted is stable, any wheels have had a brake applied and suitable provisions have been taken to stop the load from rolling. Always lift on level ground. Position the Toe Jack under a suitable lifting point. Check the release value is in the shut position, and add the pumping handle into position on the Toe Jack, now you are ready to use the jack and start lifting the load.

If Lifting via the Toe - Max capacity 6000Kgs - Make sure the Toe or claw is positioned fully under the load before lifting.

If Lifting on the head. Use the extension screw to bridge the gap first, if the object lifting point is taller than 320mm.

Start pumping the handle and the jack will start to lift the object. keep checking both the load and lifting point to make sure all is ok.

To Lower. extract the pumping handle, turn it around, and use the grooves of the handle and locate the release value, slowly turning anti-clockwise to lower the load to the floor.

Maintenance • Keep the jack clean, especially protect him from sand and water • Lubricate all gliding and moving parts thoroughly. Checking oil level Check the oil level regularly by retracting the piston fully, placing the jack in a vertical position and carefully removing the rubber oil-filler plug. The oil level should be up to the hole with the jack in a vertical position. Top-up as necessary, but do not over-fill. Replace the rubber oil-filler plug. Only use high-quality Yale hydraulic oil to Class ISO 32.

Services:

The definition of lifting equipment and accessories used in LOLER makes it clear that Jacks including hydraulic Toe Jacks are lifting equipment. Therefore all lifting jacks must be inspected at least annually not exceeding 12 months by a competent person. Adverse working conditions may dictate shorter inspection periods.

Please contact our Sales Team if you require us to carry out your annual servicing on this product or any similar products.AF162.

Hydraulic Rotational Toe Jack

Hydraulic Rotational Toe Jack

Steerman BVA Hydraulic Toe Jack

Steerman BVA Hydraulic Toe Jack

Hydraulic Rotational Toe Jack

Hydraulic Rotational Toe Jack

JH - Yale Universal Bottle Jacks

JH - Yale Universal Bottle Jacks

Machinery Toe Jack

Machinery Toe Jack

Pfaff Rotational Jack MH

Pfaff Rotational Jack MH

Add to cart

Add to cart Add to quote

Add to quote-494x340.webp)