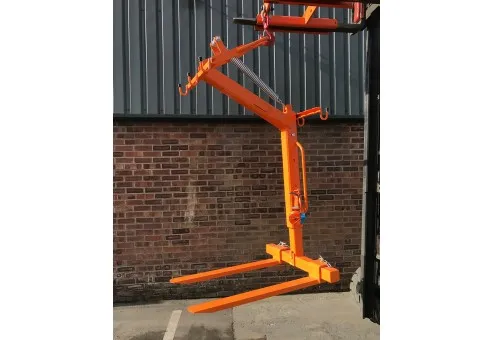

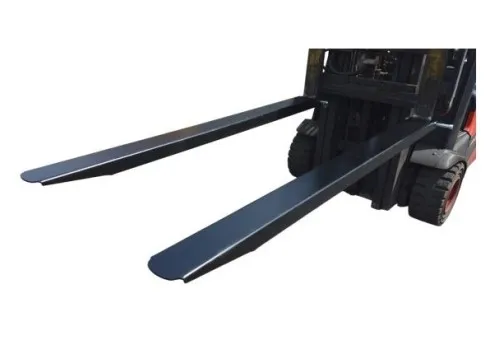

Fork Extensions - Heavy Duty Range (EFEX) manufactured from 6mm steel. Ideal for extending any forklift's reach, allowing larger and longer loads to be lifted and transported safely. Our Fork Extensions are manufactured in the UK and available from stock today. All our Fork Extensions are supplied with a 3-YEAR WARRANTY and are fully tested and certified.

Manufactured from 6mm thick durable steel in a folded channel design to offer a low-cost yet heavy-duty and strong set of forklift fork extensions. The Channel design ensures the fork extensions do not "ride Up" the back of the fork, which can potentially occur with other design styles of extensions for forklifts. The loading tip of the Forklift Extensions is finished with a rounded profile and makes positioning under the load easy connection of the fork extensions to the forklift is achieved via a heel pin that offers quick "drive-in entry" removing the need for the forklift operator to engage manually with the forklift heavy duty fork extensions. Unlike many cheaper options online these quality extensions offer many design benefits to aid in lifting and moving awkward-shaped objects.

Why Use Forklift Fork Extensions? Fork Extensions are designed to help stabilise and offer safe handling of nonstandard loads when the standard forklift-fitted tines are not long enough.

Safety Note - Even though Forklift Extensions are used to extend the forklift's reach, overbalancing can happen and the rear of the forklift could rise off the floor and tip forward. It is stated that all fork extensions should not increase the length over the original forks by more than 66% also, the width of the new Fork Extension should not be wider than 12.4mm (1/2") If in any doubt please reference the manual of the Forklift being used. Example - If the original fork tines are 1200mm long then the new Fork extensions for the forklift should be no longer than 1992mm.

Model

| Suit Fork Section

| Length

| C of G

| Overall Sleeve Width

| Overall Sleeve Depth |

EFEX100-1800

| 100 x 50mm

| 1.80m

| 794mm

| 120mm

| 65mm

|

EFEX100-2000

| 100 x 50mm

| 2.00m

| 894mm

| 120mm

| 65mm

|

| | | | |

|

EFEX125-1800

| 125 x 50mm

| 1.80m

| 799mm

| 145mm

| 65mm

|

EFEX125-2000

| 125 x 50mm

| 2.00m

| 899mm

| 145mm

| 65mm |

Please note - All Forks are sold as one pair.

If you do not see the size you require - Please contact us - as we can manufacture forklift extensions to suit any requirements.

Please note that all fork extensions from all manufacturers should not be kept on the forks permanently and should only be used to offer assistance when lifting and repositioning larger loads or to offer stability when required.

This Product is supplied with a 3-year Manufacturer warranty, fully tested & certificated.

Key Features and Benefits with our Fork Extensions - Heavy Duty Range

Part Number

Value-engineered from durable 6mm thick steel for maximum longevity.

Four popular sizes are available.

Manufactured from pressed folded steel channel, fitted to the underside to offer additional strengthening properties.

Plated underside prevents the fork extensions from "riding up" the back of the forks.

Rounded tip profile for easy entry into and out of loads or pallets.

Removable heel pin offers 'drive in' entry, negating the need for manual handling whilst complying with manual handling regulations.

'CE' marked and supplied with Certificate of Conformity to comply with Health & Safety Regulations.

Model

| Suit Fork Section

| Length

| C of G

| Overall Sleeve Width

| Overall Sleeve Depth |

FEX100-1800

| 100 x 50mm

| 1.80m

| 794mm

| 120mm

| 65mm

|

FEX100-2000

| 100 x 50mm

| 2.00m

| 894mm

| 120mm

| 65mm

|

| | | | |

|

FEX125-1800

| 125 x 50mm

| 1.80m

| 799mm

| 145mm

| 65mm

|

FEX125-2000

| 125 x 50mm

| 2.00m

| 899mm

| 145mm

| 65mm |

Please note - All Forks are sold as one pair.

If you do not see the size you require - Please contact us - as we can manufacture to most requirements

Maintenance of Fork Extensions - Heavy Duty Range

The fork extensions should be inspected weekly for the general condition with particular attention paid

to: All weld points and Wear and distortion of extensions and heel pin attachments

Damage or failure must be reported and rectified immediately prior to re-use.

General surface rusting especially in critical areas should be treated with proprietary inhibitors, primers, and paint on a regular basis.

This product is certified for six (6) months from the date of manufacture after which it is the customer’s responsibility to have the product re-tested at an approved testing facility or inspected and logged in a register by a competent person as advised by the HSE.

Since the inception in 1974, Contact Attachments have grown there Company to become "The Quality Leader in Forklift Truck Attachments" and have – along the way – acquired an enviable reputation within the industry, of which they are rightly proud. They have always been known throughout the industry as 'Contact Attachments' the decision was made to change the company trading name officially to 'Contact Attachments Ltd' in 2008.

From holding the position as one of the first forklift truck attachment manufacturers in the UK, the company has continued to grow and prosper by adhering to the company philosophy of offering first class customer service, being on-hand to offer technical help and guidance when needed, and manufacturing a high quality product that is competitively priced within the market. Exciting new opportunities in the overseas market has also further helped develop the Contact brand beyond the UK shores.

They remain committed to serving the material handling industry, committed to maintaining the reputation as a premier solutions providers, and above all committed to providing our industry a professional, experienced and reliable source to turn to when it comes to any particular material handling problem.

Ultra Heavy Duty Fork Extensions

Ultra Heavy Duty Fork Extensions

Automatic Pallet Forks

Automatic Pallet Forks

Big Bag Lifting Frame

Big Bag Lifting Frame

Crane Pallet Fork Cage

Crane Pallet Fork Cage

Fork Extensions - Heavy Duty Range

Fork Extensions - Heavy Duty Range

Add to cart

Add to cart Add to quote

Add to quote