Forklift Snow Plough - Sprung Loaded

Estimated lead time:10 Days Delivery Call if required sooner

Please call us if you need this item sooner

& COLLECT

delivery

DELIVERY

(Call us)

Seen this product cheaper elsewhere?

We will always try to offer this product at the best price. We will do our best to not just match it but to beat it.

Price match

promise

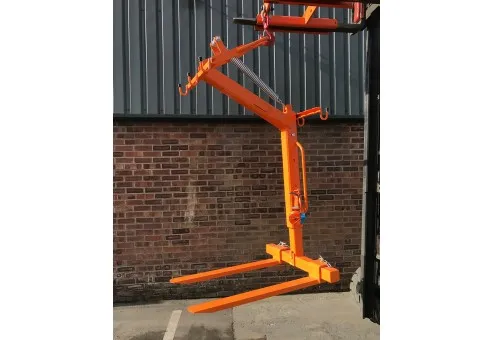

Forklift Snow Plough - Sprung Loaded

Description

Deluxe Forklift Snow Plough - Sprung Loaded version is the top-of-the-range snow plough with shock-absorbing springs fitted as standard. The Ploughing blade is also fully adjustable adjustable, allowing the plough to sweep left, right or straight on. Rubber Blades and castors fitted as standard to this premier model

£1,548.98 ex VAT

£1,858.78 inc VAT

Related products

Forklift Snow Plough Attachment

Forklift Snow Plough Attachment

ISP

£678.98 ex VAT

£814.78 inc VAT

Adjustable Snow Plough

Adjustable Snow Plough

ASP

£1,078.88 ex VAT

£1,294.66 inc VAT

Pedestrian Salt Spreader

Pedestrian Salt Spreader

PPS

£189.98 ex VAT

£227.98 inc VAT

Forklift Snow Plough (Reversible Rubber Blade)

Forklift Snow Plough (Reversible Rubber Blade)

ISP-4

Forklift Snow Plough with Polyethylene Blade and galvanised frame and interchangeable rubber blade that clears snow to left curb or right curb. Fitted with flexible hard wearing polyethylene dish that protects floor being cleared of snow

£598.98 ex VAT

£718.78 inc VAT

Heavy Duty Snow Plough

Heavy Duty Snow Plough

FSP

£694.98 ex VAT

£833.98 inc VAT

Forklift Snow Plough - Fixed Blade

Forklift Snow Plough - Fixed Blade

FMP

£648.48 ex VAT

£778.18 inc VAT

Forklift Snow Plough - Rubber Blade

Forklift Snow Plough - Rubber Blade

FMP R

£674.98 ex VAT

£809.98 inc VAT

Towable Salt Spreader

Towable Salt Spreader

SSM 190L

£648.98 ex VAT

£778.78 inc VAT

| Model | Blade Width | Blade Height | C of G | Weight |

| SSP1525 RC | 1525mm | 550 mm | 869 mm | 160 Kgs |

| SSP 1830 RC | 1830mm | 550 mm | 889 mm | 170 Kgs |

| SSP 2130 RC | 2130mm | 550 mm | 906 mm | 180 Kgs |

| Model | Blade Width | Blade Height | C of G | Weight |

| SSP1525 RC | 1525mm | 550 mm | 869 mm | 160 Kgs |

| SSP 1830 RC | 1830mm | 550 mm | 889 mm | 170 Kgs |

| SSP 2130 RC | 2130mm | 550 mm | 906 mm | 180 Kgs |

More products from category:

Forklift & Lifting Attachments

Automatic Pallet Forks

Automatic Pallet Forks

IPF

The Automatic Pallet Forks effectively convert an overhead crane into a pallet-moving tool. There are many applications where fork trucks cannot be operated due to a lack of floor space for example high rise developments.

£1,374.98 ex VAT

£1,649.98 inc VAT

Big Bag Lifting Frame

Big Bag Lifting Frame

BBL 1097

Universal Big Bag Lifting Frame is designed to lift and transport bulk bags safely and securely. It can be used with an overhead Crane, Hiab, or Forklift. Manufactured as a 4-point spreader beam suitable for 1-tonne builder's bulk bags and other oversized bags.

£444.44 ex VAT

£533.33 inc VAT

Crane Pallet Fork Cage

Crane Pallet Fork Cage

IPF-BOS-CAGE

Quality manufactured Crane Pallet Fork Cage designed to be used with Self Balancing Crane Forks to aid the safe lifting of brick packs, blocks, and other building materials at height, whilst also providing safety for any potential collapsed loads during operation

£1,142.98 ex VAT

£1,371.58 inc VAT

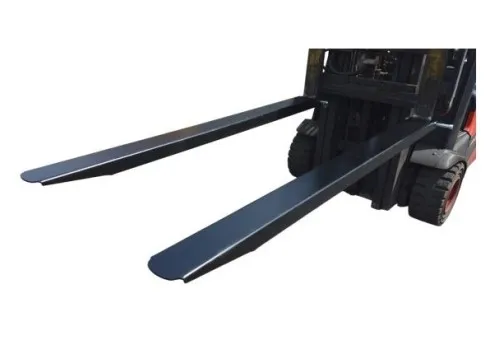

Fork Extensions - Heavy Duty Range

Fork Extensions - Heavy Duty Range

EFEX

£259.98 ex VAT

£311.98 inc VAT

SUBSCRIBE FOR THE LATEST NEWS & SPECIAL OFFERS

Sign up here to get the latest news, updates and special offers delivered to your inbox.

Add to cart

Add to cart Add to quote

Add to quote