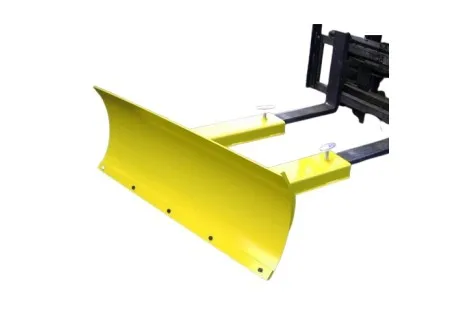

Quality UK manufactured Forklift Snow Plough - Fixed Blade version that is angled to clear snow on car parks, schools, roads, and farm yards. The snow plough comes fitted as standard with a heavy-duty steel wear strip that is designed to work in the most arduous of bad weather snow conditions and is suitable for both ploughing fresh fallen snow or hard compacted frozen snow.

Finished in a high-quality powder-coated finish to help protect against rust. The heavy-duty wear strip can be replaced with a 20mm thick rubber insert if desired.

The FMP Fork Mounted Snow Plough should be pushed along utilising either the steel or rubber blade wear strip (depending on the model purchased). the blade should be "just" in contact with the surface to be cleared of snow.

Choosing between Steel Blade or Rubber Blade

Steel Blades for Heavy Duty Operations - Ideal for ploughing frozen compacted snow. (In addition, for added service life, all snow ploughs come fitted with 10mm thick steel (replaceable) wearstrips.

Rubber Blade Insert - Acts as a form of protection for the snow plough blade, when ploughing over rough ground or over ground with raised objects (drains etc). The rubber blade insert also contributes to a longer service life of the snow plough blade.

Model

| Blade Width

| Blade Height

| C of G | Weight |

| FMP 1220 | 1220 mm | 517 mm | 687 mm | 90 mm |

FMP 1525

| 1525 mm | 517 mm | 708 mm | 99 mm |

FMP 1830

| 1830 mm | 517 mm | 726 mm | 108 mm |

FMP 2130

| 2130 mm | 517 mm | 740 mm | 117 mm |

Please check forklift tines before ordering - Max Fork Size 140mm x 60mm - Please contact Ultimate Lifting Solutions if large fork pockets are required.

This Product is supplied with a 3-year Manufacturer's warranty, fully tested & certificated.

Key Features of the FMP Forklift Snow Plough - Fixed Blade.

Heavy-duty steel blade rolling for complete durability and longevity.

Angled blade, ensures snow is pushed away to one side when ploughing.

Heavy-duty steel wear strips fitted as standard to all models with the option of additional 20mm thick rubber blade inserts.

Generous-sized fork pockets ensure the forklift snow plough will fit most fork trucks, thus maximising the use of available plant machinery.

Quick and easy to fit on and off the forklift forks via zinc-plated safety screw clamps.

No moving parts, offering low maintenance and servicing costs.

'CE' marked and supplied with Certificate of Conformity to meet Health & Safety Regulations.

Optional Accessory

Rubber Blade Scraper - Will protect both the road surface and the snow plough while in operation - Can also be used as the yard scraper in warmer months.

Simple Operation

Re-position the forklift forks to the correct distance apart to locate into the fork pockets of the snow plough.

Drive the forks of the forklift fully into fork pockets and tighten thumb screws ensuring that they are adequately tightened to lock the plough in place.

The attachment is now ready for use to clear snow from around the carpark, yard, factory area or farm.

How to Fit Snow Plough to Forklift

To fit - Simply ensure the screw clamps are loosened enough to allow initial fork entry, then simply drive the truck slowly forwards into the pockets until as far in as possible. Then simply re-tighten the screw clamps to secure onto the forklift tines.

Key Features of the FMP Forklift Snow Plough - Fixed Blade.

Heavy-duty steel blade rolling for complete durability and longevity.

Angled blade, ensures snow is pushed away to one side when ploughing.

Heavy-duty steel wear strips fitted as standard to all models with the option of additional 20mm thick rubber blade inserts.

Generous-sized fork pockets ensure the forklift snow plough will fit most fork trucks, thus maximising the use of available plant machinery.

Quick and easy to fit on and off the forklift forks via zinc-plated safety screw clamps.

No moving parts, offering low maintenance and servicing costs.

'CE' marked and supplied with Certificate of Conformity to meet Health & Safety Regulations.

Model

| Blade Width

| Blade Height

| C of G | Weight |

| FMP 1220 | 1220 mm | 517 mm | 687 mm | 90 mm |

FMP 1525

| 1525 mm | 517 mm | 708 mm | 99 mm |

FMP 1830

| 1830 mm | 517 mm | 726 mm | 108 mm |

FMP 2130

| 2130 mm | 517 mm | 740 mm | 117 mm |

Please check forklift tines before ordering - Max Fork Size 140mm x 60mm - Please contact Ultimate Lifting Solutions if large fork pockets are required.

Optional Accessory

Rubber Blade Scraper - Will protect both the road surface and the snow plough while in operation - Can also be used as the yard scraper in warmer months.

Simple Operation

Re-position the forklift forks to the correct distance apart to locate into the fork pockets of the snow plough.

Drive the forks of the forklift fully into fork pockets and tighten thumb screws ensuring that they are adequately tightened to lock the plough in place.

The attachment is now ready for use to clear snow from around the carpark, yard, factory area or farm.

How to Fit Snow Plough to Forklift

To fit - Simply ensure the screw clamps are loosened enough to allow initial fork entry, then simply drive the truck slowly forwards into the pockets until as far in as possible. Then simply re-tighten the screw clamps to secure onto the forklift tines.

MAINTENANCE of FMP Forklift Snow Plough - Fixed Blade.

The Fork Mounted Snow Plough should be inspected weekly for general condition with particular attention paid to:

A – All weld points,

B – Wear and distortion of fork pockets and thumb screws,

C – Any damaged/worn components

Any damage or failure found must be reported and rectified immediately prior to re-use of the attachment.

General surface rusting especially in the critical areas should be treated with proprietary inhibitors, primers and paint on a regular basis.

Regular inspection of the wear blade should be made and its position adjusted so as to ensure that the main snowblade is clear of wear.

After each use clean the plough down with water to remove any salt residue.

Why Choose the Contact Attachments Forklift Snow Plough

Tested & Certificated:

All Contact’s forklift snow ploughs are ‘CE’ marked, fully tested and come supplied with Certificates of Conformity for compliance with Health and safety regulations.

Design For Strength:

A Contact forklift snow plough has undergone stress analysis checks that make sure all weak points that may occur during heavy snow ploughing operations are eliminated.

Steel Blades For Heavy Duty Operation:

All Contact’s snow ploughs for forklifts are manufactured from durable 6mm thick steel, making them ideal for ploughing frozen compacted snow. In addition, for added service life, all snow ploughs come fitted with 10mm thick steel (replaceable) wear strips.

Rolled Blade Design:

To allow for efficient snow ploughing, all Contact’s forklift snow ploughs are designed with a rolled blade. A rolled blade design ensures snow rolls away from the snow plough blade in an effective and efficient manner.

Rubber Blade Inserts:

When choosing a Contact snow plough attachment, our fixed blade snow plough can come supplied with a rubber blade insert as an option, whereas our Adjustable and Sprung Loaded snow ploughs have rubber blade inserts fitted as standard. This rubber blade acts as a form of protection for the snow plough blade when ploughing over rough ground or over ground with raised objects (drains etc). The rubber blade insert also contributes to a longer service life of the snow plough blade.

Available In Various Specifications To Suit Your Needs:

Whatever the type of snow plough attachment you are looking for, Contact has a snow plough to suit your needs. From a fixed blade design for simple yet effective snow ploughing, an adjustable blade design, with left, right or centre blade positioning, to a Sprung Loaded design with shock absorbing springs, you can be assured we have a snow plough attachment to suit your requirements.

We hope the above helps demonstrate the quality and features of a Contact forklift snow plough bought from Ultimate Lifting Solutions, and welcome the opportunity to supply you with a high-quality snow plough attachment that will assist in your snow ploughing needs.

Forklift Snow Plough Attachment

Forklift Snow Plough Attachment

Adjustable Snow Plough

Adjustable Snow Plough

Pedestrian Salt Spreader

Pedestrian Salt Spreader

Forklift Snow Plough (Reversible Rubber Blade)

Forklift Snow Plough (Reversible Rubber Blade)

Heavy Duty Snow Plough

Heavy Duty Snow Plough

Forklift Snow Plough - Rubber Blade

Forklift Snow Plough - Rubber Blade

Forklift Snow Plough - Sprung Loaded

Forklift Snow Plough - Sprung Loaded

Towable Salt Spreader

Towable Salt Spreader

Automatic Pallet Forks

Automatic Pallet Forks

Big Bag Lifting Frame

Big Bag Lifting Frame

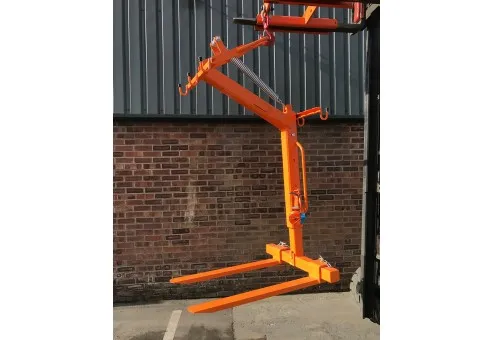

Crane Pallet Fork Cage

Crane Pallet Fork Cage

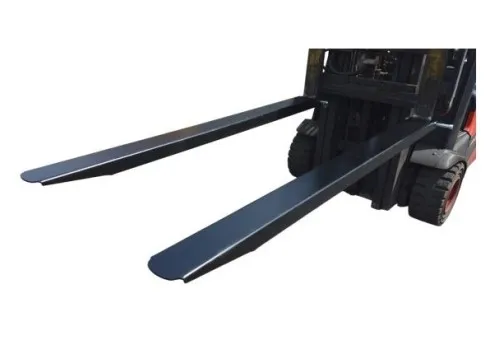

Fork Extensions - Heavy Duty Range

Fork Extensions - Heavy Duty Range

Add to cart

Add to cart Add to quote

Add to quote